Laserdyne 430

The flexible laser machining platform for a wide range of high-precision applications

VANTAGGI

Reliability and accuracy

Rugged, high accuracy, reliable laser processing with excellent process capability

Well-suited for the most demanding process validation requirements but also for the toughest factory environments

Flexibility

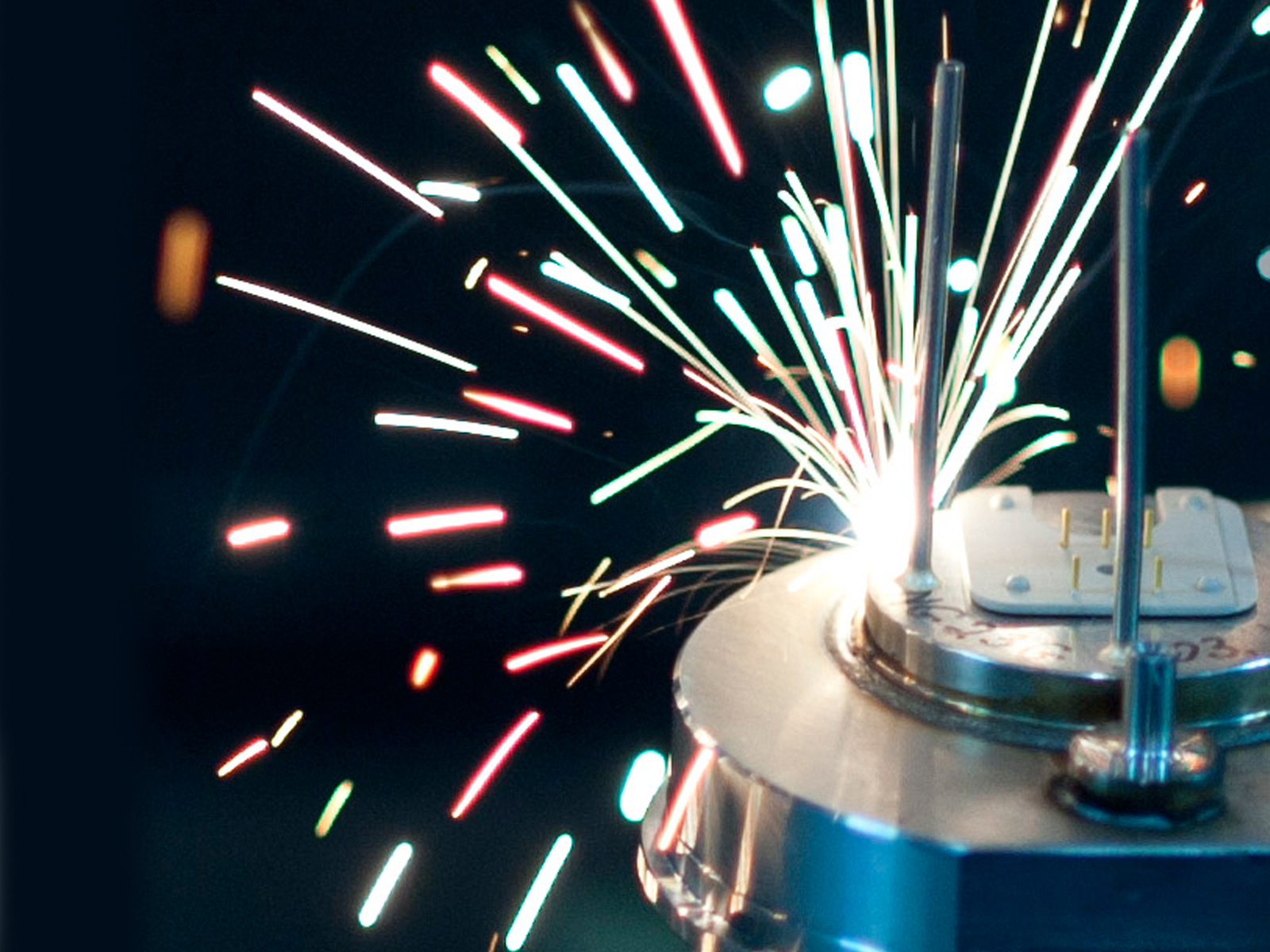

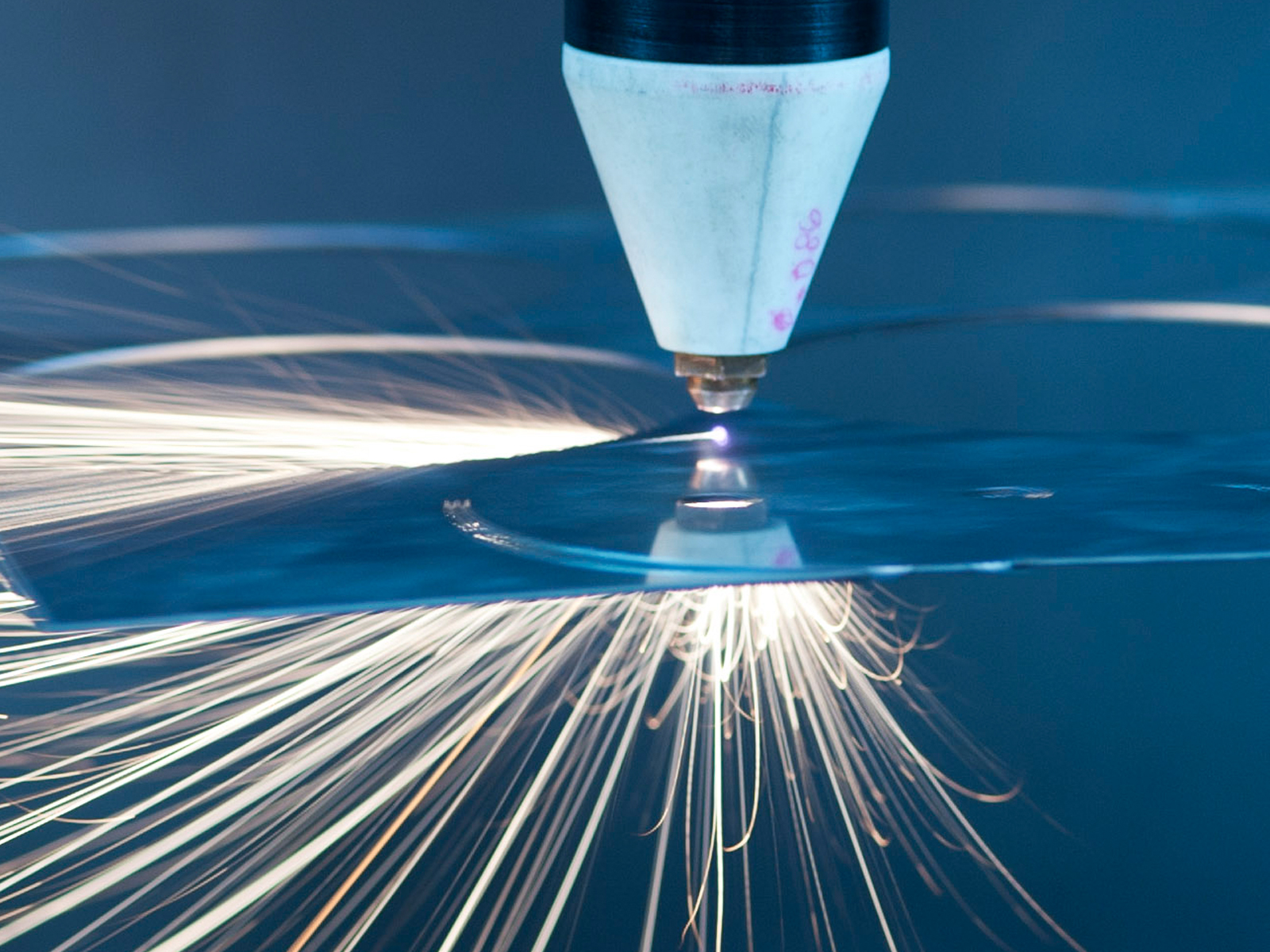

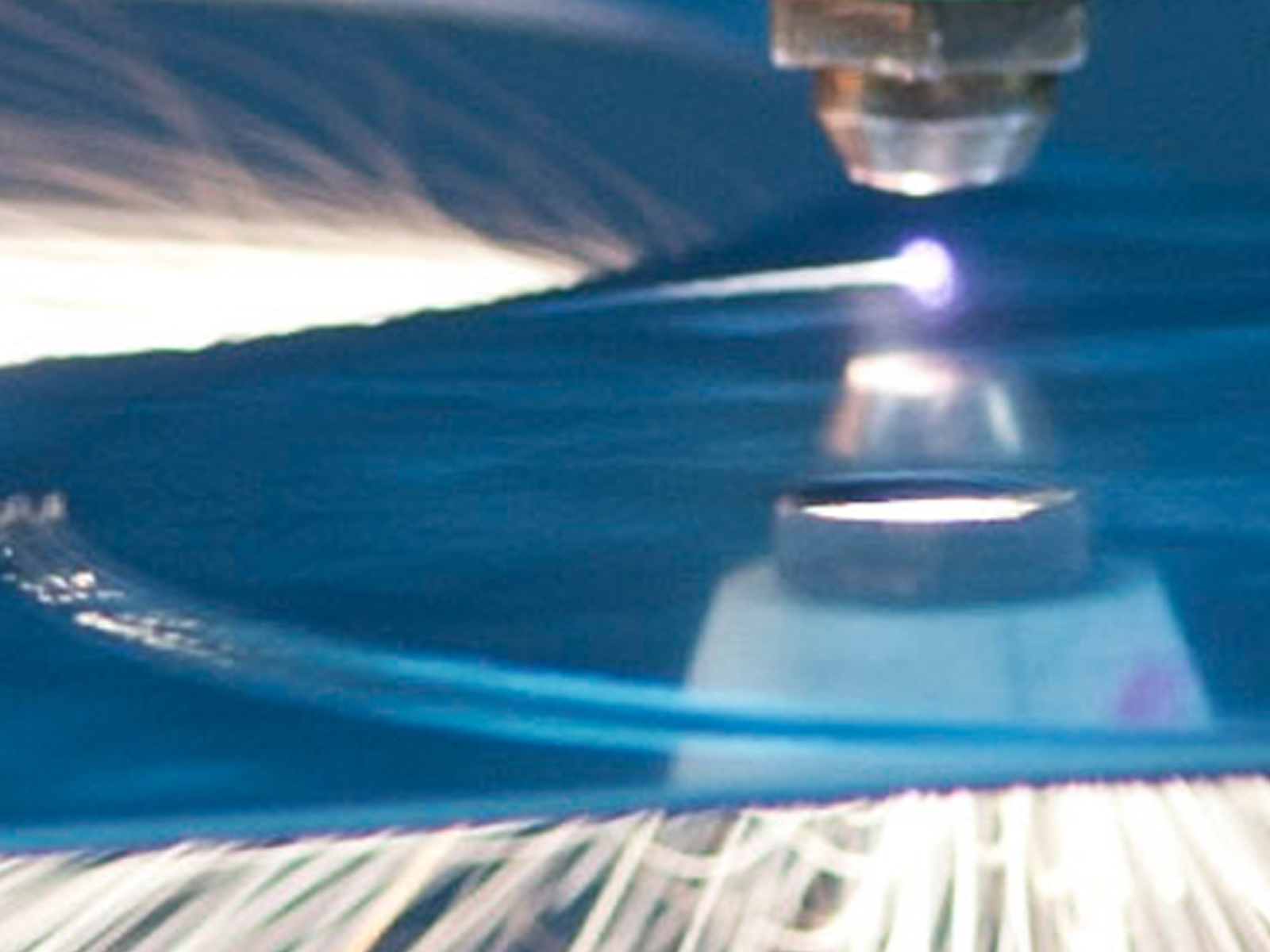

Versatile machining center construction for multi-purpose: cut, weld, drill

Wide range of laser sources available

IMPATTO AMBIENTALE

- All forms of energy efficient laser sources

- Low operating costs and minimal maintenance

- Easy user access and operation

DATI TECNICI

-

Work area

3-4 axes:

X 585 mm, Y 400 mm, Z 500 mm, Rotary 360° (optional)5-6 axes:

X 585 mm, Y 400 mm, Z 500 mm, C 900°, D 300°, Rotary 360° (optional) -

Axis speed

3-4 axes:

X, Y, Z: 15 m/min; Rotary: various options5-6 axes:

X, Y, Z: 15 m/min; C, D: 90 rpm; Rotary: various options -

Accuracy

3-4 axes:

X,Y,Z: 12.5 µm; Rotary: various options5-6 axes:

X,Y,Z: 12.5 µm; C, D: +/- 6 arc-sec; Rotary: various options -

Laser source CW, QCW, pulsed fiber laser

The choice for your toughest applications

The LASERDYNE® 430 workstation was designed for precision laser processing for a wide range of metal and non-metal cutting, welding and drilling applications. The LASERDYNE 430 is suitable in the aerospace, automotive, medical devices, electronics, industrial and consumer products industries.

Highlights

Designed from a vertical machining center platform, the 430 provides rugged, high-accuracy laser processing that will perform reliably and with excellent process capability.

5-6 axis version includes 3rd generation BeamDirector (BD3Y) with unmatched compactness and access to 3D workpieces.

Multiple levels of crash protection to prevent the system and workpiece.

Highly flexible welding and cutting performance thanks to customer proven LASERDYNE technology.

Easy load position and height and easy access from the front and both sides for tooling or automation.

Class 1 laser safety enclosure.

Dual processor design enables solid machine performance and powerful yet easy to learn user interface.

Massive worktable for mounting a wide range of custom workholding for current and future applications.

Wide range of fiber laser sources available to precisely meet specific customer requirements.

Air conditioned electronics ensures long-life and reliability in any factory environment.

LASERDYNE System S94P console with pendant controller, providing both programmable flexibility and process capability. It includes many technically advanced features:

- Automatic Focus Control™

- Surface mapping

- Integral CCTV setup and process monitor

- SPC data acquisition